Bopp Slitting Rewinding Machine 2100mm Manufacturers – Automatic Online Inspection and Rewinding Machine – JINYI

Bopp Slitting Rewinding Machine 2100mm Manufacturers – Automatic Online Inspection and Rewinding Machine – JINYI

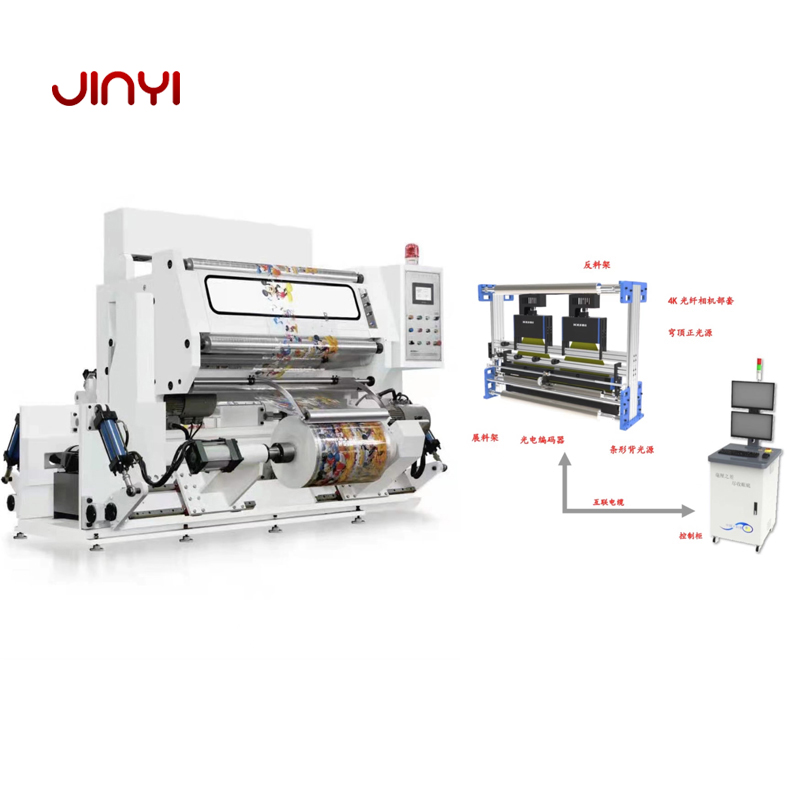

Bopp Slitting Rewinding Machine 2100mm Manufacturers – Automatic Online Inspection and Rewinding Machine – JINYI Detail:

Feature

1.Imported PLC for centralized control with touch screen operation.

2.Shaft-less for unwinder&rewinder, hydraulic lifting, convenient for material changing.

3.Inspection system adopts fully auto image-scanning device for checking out defect

4.Film absorbing type material connecting platform

5.Unwinder is equipped with EPC system

6.The system has function of meter counting, roller diameter calculation,auto stop when film breaking.

Main technical parameters

| Model | FHYB-1250 |

| Suitable material | Plastic film & laminated plastic film 12-180mic PE、PVC 40-150 mic |

| Web width | 400—1250 mm |

| Max. diameter of unwinder | Φ800 mm |

| Max. diameter of rewinder | Φ800 mm |

| Max. width of raw material | 1250 mm |

| Maximum mechanical speed | 320m/min |

| Inspecting speed | 30-300 m/min |

| Diameter of paper tube | 3″(internal diameter φ76mm external diameter φ92mm) |

| Power of unwinding motor | 4 kw |

| Power of winding motor | 4 kw |

| Power of traction motor | 4 kw |

| Total power | 13 kw |

| Weight | 3500 kg |

| Dimension(LxWxH) | 3800x3400x2150 mm |

Unwinding

part Structure

●shaftless pneumatic cone top discharge rack, discharge rack can be hydraulic lift, and can be wide and narrow

●LPC lateral correction mechanism

●Tension automatic control

●Motor take the initiative to unwind, with winding function

Specifications

●Roll width range 400 ~ 1250 mm

●Unwinding diameter (Max) φ800 mm

●unwinding motor power 4kw

●LPC lateral correction accuracy ± 0.4 mm

Feature

●shaft-free cone-shaped top-release rack, and hydraulic lift, up and down fast and convenient.

●With LPC to ensure rewinding neatly

●Tension The vector tension is automatically calculated by the PLC to achieve automatic tension control, making the tension control of the film more scientific and more accurate

●The motor automatically let the tension control range, no residual torque, tension control accuracy

●unwinding motor can be positive and negative rotation, you can roll forward when the forward, but also when the reverse winding

Adjusting roller and guide roller

Structure

●Adjustable structure is in manual form

●Adjust the roller at one end and adjust the other end

●Adjustable roller, guide roller are imported bearings

Specifications

●Adjustment roller diameter φ100 mm

●Adjustment roller length 1300 mm Adjustable range ± 20 mm

●Guide roller diameter φ100 mm

●Guide roller length 1300 mm

Features

●Adjust the roller mechanism to adapt to different quality of the film

●roller dynamic balance, making the machine without vibration source, smooth operation

●The use of imported high-precision bearings make the roller in the high-speed rotation smoothly, reduce the machine noise

Printing inspection

●Install the memory stop device and find the defective product. The defective product can be automatically retreated to the observation screen.

●The observation screen is a milky white plexiglass screen with light

source

Rewinding roll

Structure

●swing arm frame

●Clutch is in manual form

Specifications

●Roller diameter φ80mm

●The length of the roller is 1230 mm

Receiving Department

Structure

●no shaft pneumatic cone top of the receiving rack, the receiving rack can be hydraulic lift, and can be wide and narrow

●Tension automatic control

●Motor take the initiative to roll, with unwinding function

Specifications

●Roll width range 400 ~ 1250 mm

●Winding diameter (Max) φ800 mm

●Winding motor power 4kw

Features

●non-axis pneumatic cone top-type reeling rack, and hydraulic lift, up and down roll fast and convenient.

●Tension The vector tension is automatically calculated by the PLC to achieve automatic tension control, making the tension control of the film more scientific and more accurate

●The motor is automatically wound so that the tension control range is large, there is no residual torque, and the tension control precision is high

●winding motor can be positive and negative rotation, you can rewind when the forward, but also when the volume rewind

Rewinding part

●High-strength low-stress alloy cast iron wall panels

●wall panels by the second stress to eliminate, good stability

Pneumatic hydraulic system

●The machine is more use of pneumatic and hydraulic actuators, from the panel centralized operation, through the implementation of the solenoid valve, a higher degree of automation, reduce labor intensity Electrical control system

●using man-machine interface, PLC centralized control, advanced technology

●man-machine interface, display and set the host speed, winding length, put, winding tension set, taper settings

Machine packing and delivery

Product detail pictures:

Related Product Guide:

What Should Be Paid Attention When Using The Slitting Machine?

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Bopp Slitting Rewinding Machine 2100mm Manufacturers – Automatic Online Inspection and Rewinding Machine – JINYI , The product will supply to all over the world, such as: Doha, Lahore, Yemen, We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We are able to also provide you with no cost samples to meet your needs. Best efforts will be produced to offer you the very best service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our products and enterprise. lot more, you'll be able to come to our factory to find out it. We will constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. Please really feel absolutely free to make contact with us for small business and we believe we will share the top trading practical experience with all our merchants.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.