High Quality Pvc Slitting Machine Manufacturer – 1300mm Width 400m/Min Plastic Film And Paper Slitting Rewinding Machine – JINYI

High Quality Pvc Slitting Machine Manufacturer – 1300mm Width 400m/Min Plastic Film And Paper Slitting Rewinding Machine – JINYI

High Quality Pvc Slitting Machine Manufacturer – 1300mm Width 400m/Min Plastic Film And Paper Slitting Rewinding Machine – JINYI Detail:

Feature

1.Max slitting speed 400 m/min

2.Suitable material: BOPP, CPP, PET, PVC, PE, NYLON, plastic films etc…

3. Max diameter of unwinder:φ800 mm, Max diameter of rewinder:φ600 mm

4.PLC program system for automatic tension control.

5. Unwinding is shaft-less, controlled by servo motor, with hydraulic type web rolls lifting.

6.Unwinding with EPC.

7.Rewinding controlled by servo motor.

8.Rewinding use double friction slippery shaft.

9.Traction controlled by servo motor

10.Imported PLC integrated control is used in electrical control system, human-machine communication is carried out by touch screen, Set and display working parameters according to the requirements from different products.

11.Servo motor is adopted for unwinding, roll diameter is automatically calculated by PLC to achieve automatic tension control, unwinder shaft-less with EPC. Hydraulic lifting web rolls system, easy unloading and loading material.

12.Servo motor is adopted for rewinding, active winding, roll diameter is automatically calculated by PLC to achieve automatic tension control, double slip air shaft for good & stable tension.

13. Using the flat knives for slitting , regularity disc surface , air exhausting device for waste .

14. In the system, there are calculations of meter, roll diameter, automatic machine stop when lack of material etc.

15. The system has perfect mechanical, electric and pneumatic design, also good safety protection.

16.Rewinding with double friction slippery shaft.

Main technical parameters

| Unwind width | 400 – 1300mm |

| Slitting material | BOPP, CPP Film12-180um, PE, PVC, PET Film 40um – 150um. |

| Maximum unwind diameter | Φ800 mm |

| Maximum rewind diameter | φ600 mm |

| Paper Core Diameter | 3’ 6’ for unwinder/3’ for rewinder(Standards) |

| Maximum machine speed | 400 m/min |

| Min. Slitting width | 30 mm |

| Range of slitting width | 30 – 1300mm |

| Unwinding motor | 4kw |

| Traction motor | 3kw |

| Rewinding motor | 5.5kw |

| Total power | 12 kw |

| Machine size | 2300 x 4200 x 2000mm |

| Machine mass | 4000kg |

| Machine colour | Milky white(also can according customer requirement ) |

Specification

Unwind unit

Structure

● Shaft-less unwinding material loading

● Hydraulic roll material lifting

● EPC lateral correction

● Automatic tension control by PLC program from Siemens

Configurations

● Material roll width: 400-1300mm

● Maximum unwind diameter:φ800mm

● Unwinding controlled by servo motor

Features

● Shaft-less for easy material loading

● EPC for accurate no trim rewinding

● Tension by Magnetic powder clutch and

PLC automatically calculates mother roll

diameter, controlling the unwind tension.

Traction system

Structure

● Servo motor drive

● Synchronized belt drive

● Photoelectric eyes for line position control

● Rubber nip roller, pressure adjusted by pneumatic regulator

● adopt import Bearing NSK

Specification

● Driving roll diameter 130mm

● Rubber roll diameter 100mm

● Rubber roll max pressure 200kg

● Driving roll length 1350mm

● Traction motor power 3kw

Features

● Traction system, unwind and rewind tension independent

● Imported rubber roll and synchronization belt allows the driving accurate control

● Low noise

● Servo motor allows the drive and tension to be stable and precise transmission.

Slitting Unit

● Flat knife for slitting plastic films.

● Max. slitting speed 400 m/min

● Waste trim extractor

Rewind unit

● Rewind with double slip air shaft, make the production more uniform and tidy

● Automatic tension control by PLC program

● Maximum rewind diameter:φ600mm

● Tension adopts servo motor and PLC automatic calculate the diameter, then control the tension; this makes the material tension control more accurate.

Material Unloading

● Adjustable swing arm for material unloading.

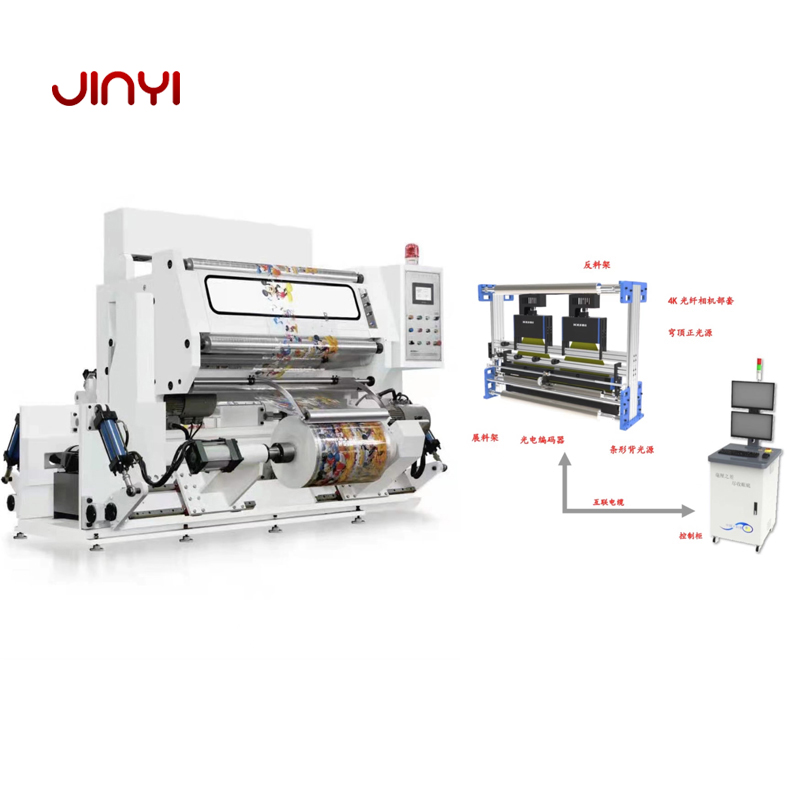

Machine photos

Electrical and Electronic Components

| Traction servo motor | DANMA,SHANGHAI |

| Unwinding servo motor | DANMA,SHANGHAI |

| Rewinding servo motor | DANMA,SHANGHAI |

| Inverter | YASKAWA, JAPAN |

| PLC | SIEMENS |

| EPC | BIANFU CCD |

| Man–machine face | WEINVIEW, TAIWAN |

| Slippery-proof belt | GERMANY |

| Electrical proportion valve | SMC,JAPAN |

| Railway | THT,JAPAN |

| Main pneumatic part | AIRTAC,TAIWAN |

| Main Bearing | NSK,JANPAN |

| Low-voltage apparatus | SCHNEIDER FRANCE |

Product detail pictures:

Related Product Guide:

What Should Be Paid Attention When Using The Slitting Machine?

With advanced technologies and facilities, strict high quality regulate, reasonable price tag, excellent support and close co-operation with shoppers, we have been devoted to furnishing the best benefit for our buyers for High Quality Pvc Slitting Machine Manufacturer – 1300mm Width 400m/Min Plastic Film And Paper Slitting Rewinding Machine – JINYI , The product will supply to all over the world, such as: Sacramento, Indonesia, Uganda, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.