Plastic Bag Laminating Machine Exporters – 80m/Min Plastic Film and Paper Window Bag Dry Laminating Machine – JINYI

Plastic Bag Laminating Machine Exporters – 80m/Min Plastic Film and Paper Window Bag Dry Laminating Machine – JINYI

Plastic Bag Laminating Machine Exporters – 80m/Min Plastic Film and Paper Window Bag Dry Laminating Machine – JINYI Detail:

Features

1. Unwind air shaft is controlled by powder brake

2. Rewind air shaft is controlled by torque motor

3. Each unwind has EPC device to prevent the material from moving left or right.

4. Oven 7.5meter, open and close is manual

5. Gluing with anilox roller which is shaftless installation

6. Manual doctor blade

7. Lamination part is controlled by inverter motor,lamination roller is heated by heat-conducted oil

Technical parameter

|

Model |

YWGF800A |

YWGF1100A |

|

Laminating layers |

2 |

2 |

|

Laminating width |

800mm |

1100mm |

|

Unwind diameter |

600mm |

600mm |

|

Rewind diameter |

800mm |

800mm |

|

Laminating speed |

80m/min |

80m/min |

|

Max oven temperature |

80℃ |

80℃ |

|

Max heat drum temperature |

90℃ |

90℃ |

|

Power |

50KW |

60KW |

|

Weight |

6000KG |

7000KG |

|

Dimension |

9000*1960*2550mm |

9000*2260*2550mm |

YWGF800A Model

Main parameter

1).Laminating layer:2 layers

2).Suitable material

BOPP 18-100μm

CPP 20-100μm

PET 12-100μm

Alu foil

Metalized film

Paper 18-60μm

PC

3).Laminating width: 800mm (800 model)

4).Material diameter: 600mm

5).Laminating speed: 5-80m/min

6).Max oven temperature: 80℃

7).Max heat drum:70-90℃.

8).Max laminating pressure: 10MPA

9).Tension draw ratio: <<1/1000

First Unwinding(auto cylinder loading ) convenient for loading heavy raw material

Structure

1). EPC.

2).Magnetic powder manual tension control.

3).The roll horizontal adjustment is manual

4).Air shaft

Specification

1).Max roll dia: Φ600mm

2).Roll horizontal correcting: ±60mm

3).Tension set: max 50N/m

4).Tension controlling precision: ±0.1kg

5).Max unwinding width: 800mm

6).Roll horizontal adjustment: ±20mm

Drying Part

Structure

1)Electric heating.

2)Waste air exhausting tunnel.

3)4 pace intelligent temperature control, material protecting roller and hot drum run synchronously.

Specification

1)Max temperature:80℃

2)Material length in the oven:75000mm

3)Blower mouth: 24 pieces

4)Max temperature controlling precision: ±2℃

5)Max intake air: 1200m³/h

6) Blower power: 1.1KW

Second unwinding part

Structure

1).EPC.

2).Magnetic powder manual tension control.

3).The roll horizontal adjustment is manual

4).Air shaft

Specification

1).Max roll dia: Φ600mm

2).Roll horizontal correcting: ±60mm

3).Tension set: max 50N/m

4).Tension controlling precision ±0.1kg

5).Max unwinding width: 800mm

6).Roll horizontal adjustment ±20mm

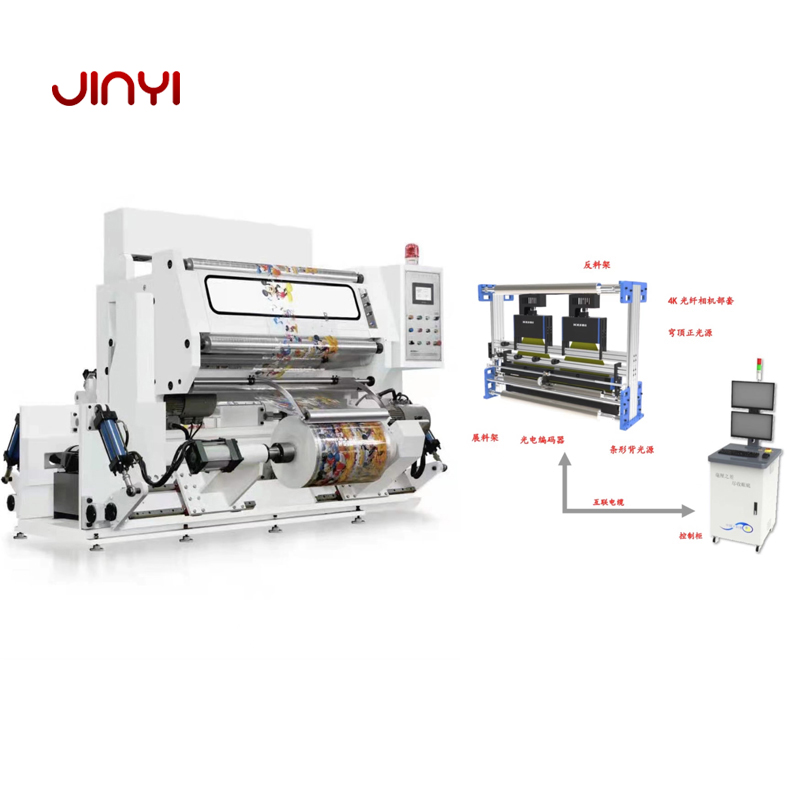

Product detail pictures:

Related Product Guide:

What Should Be Paid Attention When Using The Slitting Machine?

With a sound enterprise credit history, exceptional after-sales services and modern production facilities, we've earned an outstanding track record amongst our consumers across the whole world for Plastic Bag Laminating Machine Exporters – 80m/Min Plastic Film and Paper Window Bag Dry Laminating Machine – JINYI , The product will supply to all over the world, such as: Melbourne, Milan, Azerbaijan, Certainly, competitive price, suitable package and timely delivery will be assured as per customers' demands. We sincerely hope to build business relationship with you on the basis of mutual benefit and profit in the very near future. Warmly welcome to contact us and become our direct cooperators.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!