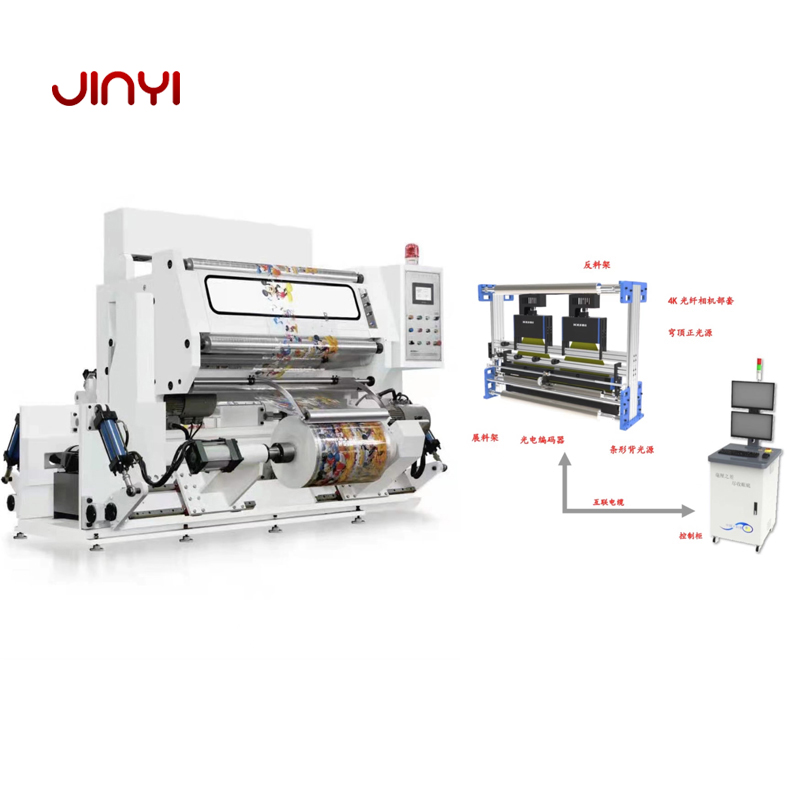

China Wholesale Pvc Label Film Slitting Rewinding Machine – FHYA-B 1300 Bopp,Pet,Cpp,Pvc and Paper Inspection and Rewinding Machine – JINYI

China Wholesale Pvc Label Film Slitting Rewinding Machine – FHYA-B 1300 Bopp,Pet,Cpp,Pvc and Paper Inspection and Rewinding Machine – JINYI

China Wholesale Pvc Label Film Slitting Rewinding Machine – FHYA-B 1300 Bopp,Pet,Cpp,Pvc and Paper Inspection and Rewinding Machine – JINYI Detail:

Technical data

Maximum diameter of unwinding: Φ600mm

Maximum diameter of winding: Φ600mm

Width range of unwinding: 30mm~1300mm

Maximum Inspection width: 1300mm

Diameter of paper tube: 3″ and 6″ (3inch and 6inch universal use)

Maximum mechanical speed: 320m/min

Maximum Inspection speed: 300m/min

Inspection accuracy: ≤0.4 mm

Tension range: 2 – 30kg

Power of unwinding motor: 3.7KW (Servo motor)

Power of winding motor: 3.7KW (Servo motor)

Power of traction motor: 4KW(Frequency motor)

Total power: 13KW

Dimension: 2800×2200×2000mm(After wood package)

Weight: 4000kg

Applied substrate: thin film and composite membrane (0.012-0.18, PE, PVC is 0.04-0.15)also paper

Unwinding

Structure

●shaftless pneumatic cone roof-typed material frame

●LPC horizontal corrective mechanism

●Tension automatic control

●Motor unwinds automatically, it has the function of winding

Specification

●width range: 30mm~1300mm

●Diameter of unwinding (Max) φ600 mm

●Power of unwinding motor 3kw

●LPC horizontal corrective accuracy ± 0.4 mm

Feature

●shaftless pneumatic cone roof-typed material frame

●Rewinding : shaftless

●equipped with LPC guaranteeing neat rewinder

●Vector frequency-converting is adopted for winding and rewinding driving, automatic tension control is achieved through roll diameter calculated by PLC automatically.

●motor to make the large range of tension control, no residual torque, tension control of high Precision

●unwinding motor can be positive and negative rotation, rolling, can be positive when rewinding can reverse again

Offset adjustment roller and guide roller

Structure

●the offset adjustment roller is manual using silk pole and guide mechanism

●On end of the offset adjustment roll is fixed, the other end can be adjusted.

●Offset adjustment roller and guide roller use imported bearings.

Specification

●Diameter of offset adjustment roller φ100 mm

●Length of offset adjustment roller 1330 mm

●Adjustment range ±20 mm

●Diameter of guide roller Φ100

●Length of guide roller 1330 mm

Feature

●adopts offset adjustment roller for adapting to different quality of the membrane

●after dynamic balance, the machine operates smoothly without vibration

●adopts imported bearing which make the rotation in high speed stable and reduce noise

Length-counting Device

Structure

●roller-typed high-precision encoder length-counting device

●contact transmission with membrane

●the length of unwinding and winding can be set. It can be stopped automatically when reaching the set length

Feature

●accurate

Traction unit

Structure

●AC motor drive

●synchronous belt transmission

●Motor uses imported bearing

●double roll

●the regulation of tension will be completed by pneumatic component.

Specification

●diameter of drive roll φ130 mm

●top roller φ100 mm NBR Shore (A) 70°~75°

●Maximum pressure of steel roller 200kg

●Length of driving roll 1330 mm

●roller dynamic balancing accuracy ≤ 5 g

●traction motor power 4kW

Feature

●after using traction device, winding and unwinding tension can be blocked

●after balancing, the machine has no vibration, so the operation is smooth

●adopts imported bearing which make the rotation in high speed stable and reduce noise

●uses synchronous belt making transmission precise and smooth and reducing noise

●adopts AC motor drive causing stable tension, high accurate transmission, smooth and reliable operation

●the on-off of top roller is linked with the mainframe, and completed by central controller

Printing product checking

●checked by strobe lamp( stroboscope system for eye inspection )

●If defective pattern is observed, it can be turned back automatically by pressing the defect button.

●observation screen is milky white polymethlmethacrylate with light on the back and reflection light on the top

Removing waste edge material and Slitting

●With a cutting knife, waste edge can be cut off by the exhaust fan waft into the waste tank collection

Winder press roller

Structure

●swing arm rotating structure

●on-off pressure is pneumatic-typed

Specification

●diameter of roller φ80 mm

●surface length of roller 1330 mm

Feature

●pressure change with diameter, which is helpful for neat rolling and winding

●applicable to substrate of uneven thickness

Rewinding

Structure

●shaftless pneumatic cone roof-typed material frame

●Tension automatic control

●Motor winds automatically, it has the function of unwinding

Specification

●width range 30~1300 mm

●Diameter of rewinding (Max) φ1000 mm

●Power of rewinding motor 4kw

●LPC horizontal corrective accuracy ± 0.4 mm

Feature

●shaftless pneumatic cone roof-typed material frame

●equipped with LPC guaranteeing neat rewinding

●Motor winds automatically, tension control is wide and accurate, no residual torque

●unwinding motor can be positive and negative rotation, rolling, can be positive when winding can reverse again

Frame

●use high-strength low-stress alloy cast iron wall

●wall has experienced twice stress elimination with good stability

Gas hydraulic system

●It adopts aerodynamic and hydraulic mechanism, operated by the panel and implemented by electromagnetic valve with high degree of automation and low labor intensity.

●In order to ensure the adequate and reliable embodiment of machine, main pneumatic and hydraulic components are imported pieces

●It has the function of removing waste edge, waste air-conveying

12.Electrical control system

●use man-machine interface, PLC centralized control with advanced technology

●man-machine interface, display and set speed, winding length, unwinding/winding tension setting, taper setting

Machine packing and delivery

Product detail pictures:

Related Product Guide:

What Should Be Paid Attention When Using The Slitting Machine?

To become the stage of realizing dreams of our employees! To build a happier, much more united and far more professional team! To reach a mutual profit of our clients, suppliers, the society and ourselves for China Wholesale Pvc Label Film Slitting Rewinding Machine – FHYA-B 1300 Bopp,Pet,Cpp,Pvc and Paper Inspection and Rewinding Machine – JINYI , The product will supply to all over the world, such as: Mauritania, Greek, Moldova, we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We will work wholeheartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.